Highbright Compact mobilized pallet racks

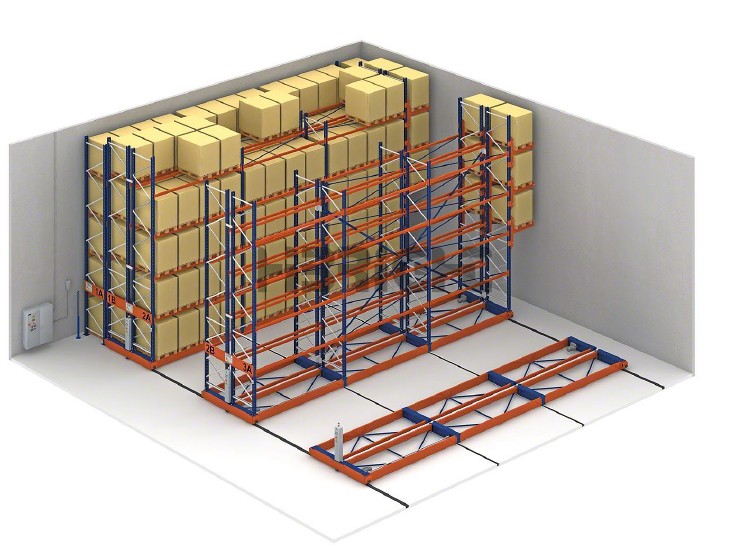

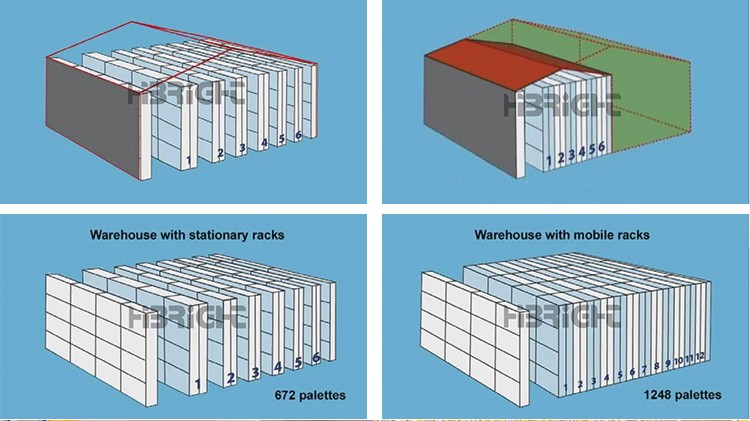

Highbright Compact mobilized pallet racks also known as motorized mobile pallet racks or mobile industrial rack system, are designed to maximize the use of warehouse storage space. Mobilized compact pallet racks can reduce your pallet storage area in half, or double the capacity of your pallet rack storage in the same floorspace area. Mobilized pallet racks save space by converting static access aisles into productive storage space. The mobilized compact rack storage system mounts rows of pallet racks onto heavy-duty rolling carriages and places them on floor tracks. Rows of pallet racks move sideways along the floor tracks creating a movable floating access aisle. Typical warehouse storage facilities may have dozens of static access aisles but only one or two forklifts capable of accessing stored materials. Mobilizing pallet racks reduce the number of access aisles to match the velocity requirements of your storage area. Rows of pallet racks are moved by pushing a button or by remote control, which opens access aisles when and where they are needed.

Mobilized pallet racks have helped many organizations reduce or eliminate new building construction costs, auxiliary warehouses, building expansions, and decrease ongoing operational costs (lighting, energy, insurance) by maximizing the use of their storage floor space.

Some disadvantages of high density pallet storage systems are; less access to all stock at any given moment (although if the stored product is all the same, it should not matter), and the expense of such systems. Selective pallet rack systems are considerably less expensive per pallet position than their higher density counterparts. In most medium to large facilities, however, high density pallet rack systems are essential, since they provide the efficiency of time and high cost facility space is better optimized.

Why to Choose Electric Mobile Racking?

1.Movement is achieved by the motor-driven bearing trolley, on which the pallet racks or cantilever racks are installed. Movement velocity is controlled by the frequency conversion modulation, so the movement is very steady. The operation safety is guaranteed.

2. Higher efficiency.

3. Order picking can be proceeded 100%.

4. The structure is simple; the operation mode is safe and reliable. The rack can move emergency when it is out of power.

5. Chainless transmission can save the Energy and makes the structure more reliable.

6. Compared with common racks, it may improve the ground utilization ratio by 80%.

Components Electric mobile racking are divided into static rack sections and motor driving sections.

1. Static Rack Section

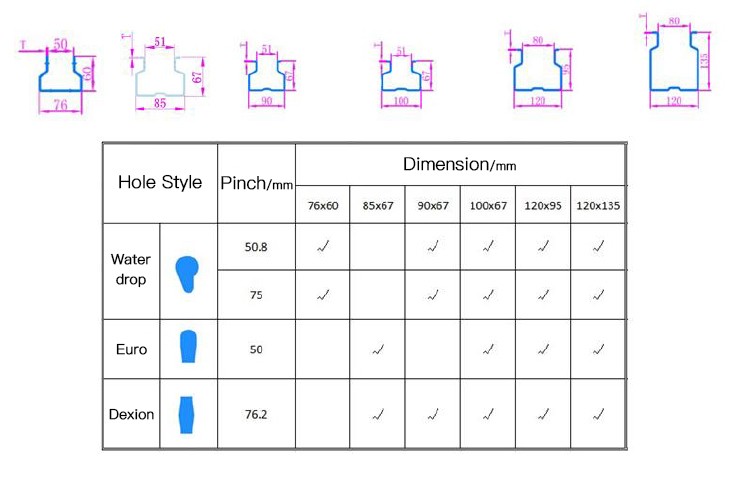

1) Specifications of Uprights:

2) Specifications of Beams :

| Name | Size |

| H | W | T |

Interlock

Beam

(mm) | 80*50*1.5 | 80 | 50 | 1.5 |

| 90*50*1.5 | 90 | 50 | 1.5 |

| 100*50*1.5 | 100 | 50 | 1.5 |

| 110*50*1.5 | 110 | 50 | 1.5 |

| 120*50*1.5 | 120 | 50 | 1.5 |

| 140*50*1.5 | 140 | 50 | 1.5 |

| 160*50*1.5 | 160 | 50 | 1.5 |

| 160*50*1.8 | 160 | 50 | 1.8 |

Step

Beam

(mm) | 110*50*1.5 | 110 | 50 | 1.5 |

| 140*50*1.5 | 140 | 50 | 1.5 |

| 160*50*1.5 | 160 | 50 | 1.5 |

P

Style

Beam

(Inch) | 3.0"*2.5"*0.06" | 3" | 2.5" | 0.06" |

| 3.5"*2.5"*0.06" | 3.5" | 2.5" | 0.06" |

| 4.0"*2.5"*0.06" | 4" | 2.5" | 0.06" |

| 4.5"*2.5"*0.06" | 4.5" | 2.5" | 0.06" |

| 5.0"*2.5"*0.06" | 5.0" | 2.5" | 0.06" |

| 5.5"*2.5"*0.06" | 5.5" | 2.5" | 0.06" |

| 6.0"*2.5"*0.06" | 6.0" | 2.5" | 0.06" |

2.Motor Driving Sections.

There are two types of mobile rack: Tracked and non-tracked Differences

1. Construction period of a non-tracked system is 10-15days shorter than a tracked one.

2. The bearing ability of the tracked system is bigger than that of the non-tracked one.

3. The height of the tracked system is higher than that of the non-tracked one.

4. The construction cost of the tracked system is lower than the non-tracked one.

Electronic mobile racking’s operation:

1. Open the aisle from the long distance---- opens the aisle by the touch screen.

2. Control from the long distance---- control from the long distance by wireless.

3. Open the aisle---- relieves all the aisles with red light on, press the corresponding button, the aisle open.

4. Move by force---- switch to the manual mode, can remove the single unit left and right.

5. Equal scatter---- the cold storage environment need the circulation of cold air, frozen evenly or stock count needed, all the aisles will be scatter equally, and working will be available inside the aisle.

6. Aisles appointed (linkage function)----when the multiple rows of racking stand together,appoint one aisle open automatically,the aisle can be setting advance,

multiple rows of racking can move at the same time.

7. Energy saving function---can be setting when out of use after some time, the power system will be shut automatically, saving the energy.

The security of electronic mobile rack

1. The photoelectric detector--- if someone breaks in the non-open aisle when the racking is operating, it will stop and alarm.

2. The photoelectric bumper--- if there are goods or people in the non-open aisle when the racking is operating, it will stop and alarm.

3. Open the lock of the aisle--- when the aisle is open, the aisle will be locked, with the red light on.

4. The power on lock each other---- when the main power is on, the aisle opened will be locked automatically.

5. The operation indicator light---- when the racking is moving, the indicating device on the racking will alarm with light and sound.

6. Stop when moving--- when the racking is moving, press the moving button on any row will stop the racking from moving.

7. Stop urgently--- when press the stop urgently button, it can cut off the power of racking.

The Racking system

Please Click the Racking System that you are interested in

Contact Us

You Choose How to Order

Either Telephone our company on:

+0086-512-58911908, 58911907, 58911906

+0086-

Fax your inquiry or order on:

+0086-512-58911909

Email to:

sales16@highbright.net

Or post to us at the address shown below:

No.19-2, Zhongxing Road, Economic Development Zone, Zhangjiagang, Jiangsu,China 215600

Our Website :

So feel free to send us your inquiry, We will do our best to serve you!