General Introduction

Storage Warehouse Heavy Duty Metal Pallet Racking Push Back Rack

If you have a plan to build a new warehouse, click here to enquiry us, we can help you from drawing to shipment

The push back pallet rack is a high density storage solution that uses heavy-duty carts to form 2 to 6-pallet-deep configurations. The pallets are arranged so that when storing pallets the last one in is the first one out (LIFO). A push back rack system fills the storage cube with product, not aisles. Each independent flow lane provides clear access to pick facings, making multiple SKU storage easy and efficien.

1,Push back rack provided highly effective use of space by combining high density storage with high speed access. Follow the principle of FILO(First In, Last Out).

2,Total depth of rack should not be too deep and dense storage within 6 pallet deep.

3,Single Cargo is generally less than 1500kg weight and the height of rack is under 6m.

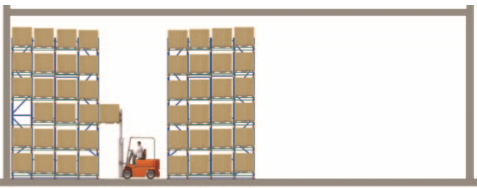

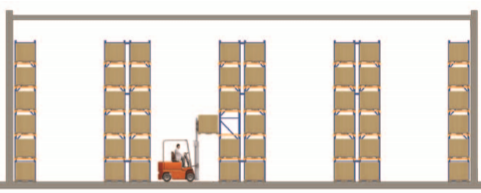

Advantages compared with conventional pallet racking

There is no wasted space with Push-back rack. Because of the increased depth of the system, Push-back minimizes the number of asles needed to access product, creating a high-density, high-efficiency storage solution. As pallets are removed, gravity pulls the remaining pallets forward, ensuring that the front pallet position is always filled. This makes pallet extraction simple. |

Push-Back Racking 90% Utilization of pallet position |

Conventional Pallet Racking 50% Utilization of pallet position |

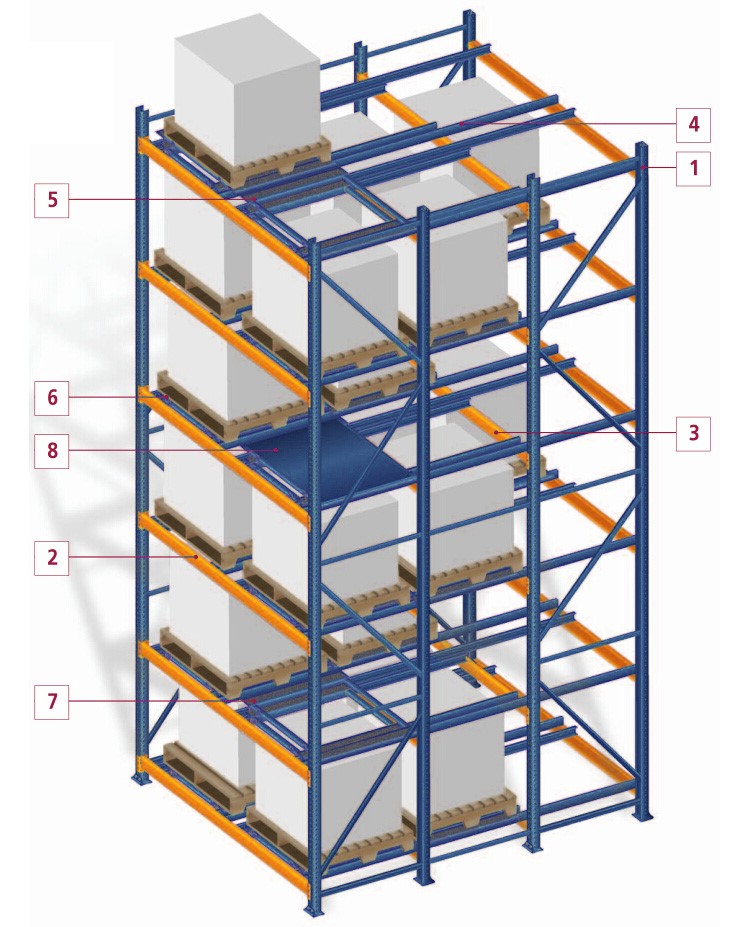

Components

1.Pallet rack frame 2.Front Beam

3.Intermediate Beam 4.Rails

5.Cart 6.Pallet stops

7.Skid-resistant surface (Optional) 8.Full cart over (Optional)

| Main components |

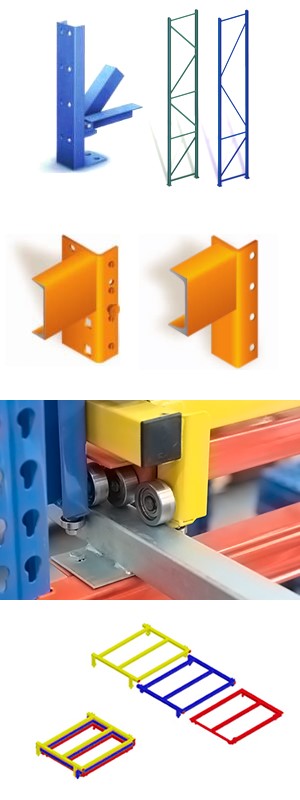

| Frames

Frames are available in welded or bolted options and consist of two posts, horizontal and diagonal struts, and foot plates. Posts are available in a variety of gauges, lengths, confi gurations for seismic zones and vertical bracing made to be more resistant to twisting, separating and axial loading. |

Beams

The beams are the horizontal rack components on which the Push-Back

carts and rails are placed. Beams are equipped with Piston Lock end plates.

These lock the beam into the post hole punches and are designed to prevent accidental collapse. For structural frame options, the end plate is bolted directly onto the posts. Interlake Mecalux uses an extensive range of beams in order to meet capacity, load type, and spacial dimension needs. |

Wheels and rails

Each cart is equipped with four electro-galvanized steel wheels, especially designed for durability and ease of movement.

Single piece structural steel channels serve as rails for each cart’s wheels.

These are installed at a pitch designed to maximize proper movement and eliminate derailment. Each channel is notched to allow cart installation or removal. |

Carts

Our welded structural steel Push-Back carts are designed for heavy-duty applications.

Each standard Push-Back cart carries a standard load of up to 1500kg. The only variance between the two-, three-, or four-

pallet deep configurations are the number of the carts and rails. |

The Racking system

Please Click the Racking System that you are interested in

Contact Us

So feel free to send us your inquiry, We will do our best to serve you!