Highbright Radio Shuttle

This high density pallet storage system simplifies loading and unloading goods by utilizing an electric cart called a Radio Shuttle.

A fork lift sets the pallet on top of the Radio Shuttle. The cart then moves along the track to place the load in the correct location.

Using a remote control, the operator can execute all procedures for storing and extracting pallets. High precision sensors control how the Radio Shuttle moves the stored load.

Components

The shuttle racking system is consisted of the shuttle racks, the radio shuttle car (pallet runner) and the forklift.

The structure of radio shuttle racking:

1.Upright 2.Top board 3.The shuttle cart 4.Guide rail 5.The pallet guide 6.Row spacer 7.Beam

The technical specification of shuttle racks

Applied pallet | L: 1100-1400mm D: 800-1500mm |

| The loading capacity | 1000-1500KG |

| Speed | Full load: 0.8m/s Empty: 1.0m/s |

| Rated Voltage | 24V |

| Working hours | >8 h |

| Charging time | 3.5h |

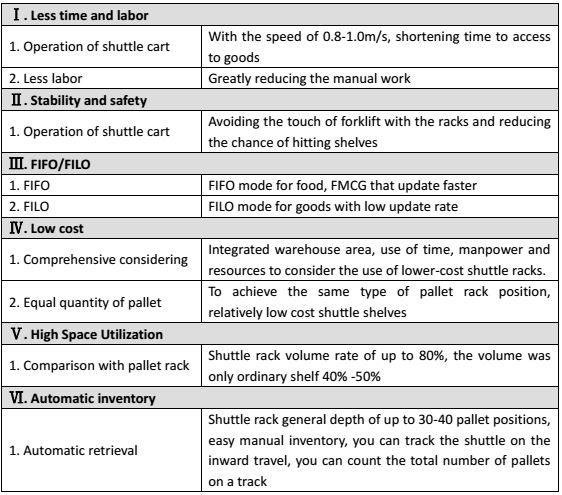

Advantage of shuttle racks

Operation Instruction of shuttle racks

1. Get in/ Get out

The shuttle cart can be adjusted to the best position of pallet lifting via the getting in and out button of the remote control. So the shuttle cart carries the goods in and out.

2. Continuous getting in/ Continuous getting out

The specialized button makes the goods to be continuous in and out possible.

3. First in first out/ first in last out

The remote control has two functions: FIFO&FILO.If the racks stop moving,all the tasks could be continued.

4. Retrieval

The shuttle cart can be placed and can move on the tunnel, which is a procedure to check and retrieve the goods.

Safety Device

1. Safety Mechanical device

1) Shuttle carts are equipped with polyurethane crash barriers to reduce the incident impact.

2) Shuttle carts have stopper to reduce the friction between shuttles and the side of tunnels.

3) At the bottom of shuttle carts, there are baffles preventing the shuttle panel falling down

when the forklifts work.

4) The handling sides are all equipped with antiskid plate.

2. Safety Electronic device

1) All the shuttle carts have sensor which will alarm when there is any block.

2) There is laser switch to monitor the shuttle cart in case that it bumps the tunnel.

3) The battery has over current protection avoiding being impaired.

4) Check the length of the pallet to ensure that the shuttle cart can support the whole pallet.

5) The shuttle cart will stop automatically to protect the motor when it rises to the limited temperature.

6) The shuttle cart has automatic checking to the position of the pallet in case that the goods fall down due to the inclination of the pallets.

7) Shuttle cart only moves on the tunnel, so it doesn’t work on the forklift.

The Racking system

Please Click the Racking System that you are interested in

Contact Us

You Choose How to Order

Either Telephone our company on:

+0086-512-58911908, 58911907, 58911906

+0086-(24 hours available)

Fax your inquiry or order on:

+0086-512-58911909

Email to:

richardling@highbright.cn

richardling@vip.sina.com

Or post to us at the address shown below:

No.19-2, Zhongxing Road, Economic Development Zone, Zhangjiagang, Jiangsu,China 215600

Our Website :

So feel free to send us your inquiry, We will do our best to serve you!